UUED TOOTED

Tootearendus on üks Arensi prioriteetidest. Järgime värskemaid köögimööbli disaini trende ning furnituuri- ja materjaliuuendusi. Rahvusvahelised mööbli- ja tehnikamessid näitavad suunda ning uued ja põnevad tooted jõuavad kiiresti meie valikusse. Koostöös maailma juhtivate materjali- ja furnituuri tootjatega on Arens ka ise köögimööbli trendide ja uute standardite looja.

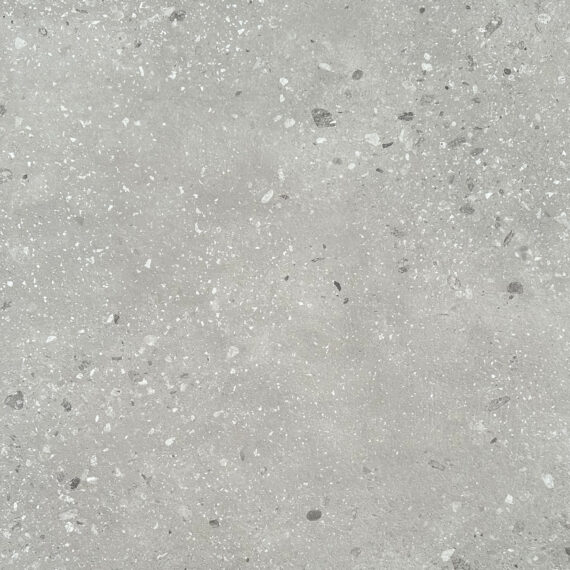

Arensi köögid on toodetud uue põlvkonna materjalide ja furnituuridega, näiteks jõuab köögi furnituur nagu sahtlid, hinged, korvid ja mehhanismid kliendini tumehallis toonis. Arensi sortimenti lisandub pidevalt uusi tooteid. Uudisena on valikus printdekooruksed, mis on äravahetamiseni sarnased naturaalsete materjalidega.

Arensi köögid on toodetud uue põlvkonna materjalide ja furnituuridega, näiteks jõuab köögi furnituur nagu sahtlid, hinged, korvid ja mehhanismid kliendini tumehallis toonis. Arensi sortimenti lisandub pidevalt uusi tooteid. Uudisena on valikus printdekooruksed, mis on äravahetamiseni sarnased naturaalsete materjalidega.

SORTIMENT

Otsekontaktid maailma juhtivate materjali- ja köögimööbli furnituuri valmistajatehastega tagavad Arensi klientidele kõrgeid kvaliteedinõudeid ja valitsevaid trende arvestava tootevaliku ning tarnekindluse. Olgu sooviks klassikaline köögimööbel, täispuidust ustega köögimööbel või modernne köögilahendus, Arens pakub köögimööbli täislahendust – valikus on kvaliteetsed ukse-, tööpinna- ja karkassimaterjalid, köögi furnituur ning köögitehnika.

Parima tulemuse saavutamiseks on soovituslik tellida köögimööbel tehnikaga, valikus on mööbel integreeritud tehnikaga või eraldiseisva tehnikaga. Arensi disainerid aitavad valida visuaalselt ja funktsionaalselt kliendi vajadustele sobiva köögitehnika ja sanitaartehnika. Arensi sortimendis on saadaval praktilised ja eksklusiivsed tooted nagu näiteks pliidiplaati integreeritud õhupuhasti, integreeritav veinikülmik ja keeva vee võimalusega segisti.

INSPIRATSIOON

Valge köögimööbel ja hall köögimööbel on täna tõsiselt konkureerimas tumedates toonides mööbliga. Eritellimusel köögimööbel loob võimaluse kombineerida ja disainida mööblit vastavalt maitsele, et luua meelepärane interjöör.

Saa inspiratsiooni galeriist, kus on läbilõige Arensi toodetud köökidest, uutest lahendustest ja disainist. Visuaalid on koos viidetega kasutatud materjalidele ja köögi furnituurile, et soovide kaardistamine ja tulevase köögi disainimine oleks mugavam.

Köögimööbli projekteerimine toimub Arensi salongis koos disaineriga, kellega leitakse sobiv lahendus. Arensi köögimööbel kujundatakse loomutruu visuaaliga 3D kujundusprogrammis Winner, tänu millele on kliendil võimalik mööblit tellides oma tulevast kööki näha fotokvaliteedis.

Disain kööki!

tellimise protsess

ARENSIST

Arens AS on 30-aastase tegutsemisajalooga Eesti köögimööbli tootja, mille 14 000-ruutmeetrises tehases on valminud üle 160 000 köögi. Arensi tootmismaht on keskmiselt 600 köögimööbli komplekti kuus. Köögimööbli müük hõlmab lisaks Eestile välisturgu, 40% toodangust läheb ekspordiks Soome, Rootsi, Norrasse, Islandile ja Lätti. Arens toodab eritellimusel köögimööblit nii eraklientidele kui ka suurprojektidele.

Arensi tootmisprotsessi iseloomustab tehnika viimase sõna järgi varustatud ja suuresti robottehnoloogial põhinev masinapark, mis tagab kõrge tehnilise- ja koostekvaliteedi.

Hoolimata automatiseeritud tootmisprotsessist tagab Arens köögimööbli valmistajana klientidele paindlikud valikud ja personaalse lähenemise. Kogu Arensi köögimööbel valmib eritellimusel.

Kirjutage meile

Kirjuta meile sõnum läbi käesoleva kontaktivormi või otse üldmeilile arens@arens.ee